THE TASKA is Supair’s first foray into the sports class. Known for decades as a harness company, Supair moved into making wings three years ago. They now have the Eona (EN A), the Leaf and Leaf Light (EN B), the lightweight Eiko (EN B) and the Sora (a tandem) in their range.

The Taska being their first EN-C wing, the design team at Supair offered to show us the design thinking that went into the wing. What better way of understanding the new wing, they suggested, than flying the Taska prototypes they had made?

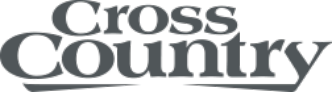

Proto 1

I arranged to rendezvous with Supair’s designer Pierre-Yves Alloix and R&D manager JC Skiera on launch at Gourdon, France. Unfortunately, most people who had turned up to fly were leaving as it was stable. However, Pierre-Yves and JC soon turned up with a van full of prototypes and the game began.

Squeezing into the weight range of the prototypes by using a lightweight Strike harness I just got in at the top weight of 95kg. JC handed me the first glider. “This is our first proto from November 2014,” he said. Did I hear that right? Yes, they confirmed that the Taska project started two-and-a-half years ago.

Making the best of the tricky conditions I launched and managed to soar the ridge, gaining height in the thermals coming through. The wing felt remarkably normal for a first proto, in fact I felt really comfortable on it. The handling was nice, if a little on the relaxed side, and it soaked up the bumps well, as you would expect for a middle EN C.

“When we flew this we thought, ‘Great this is going to be a really easy project,’ as it flew really nicely,” JC explained. “I took it to Colombia in early 2015 and loved it.”

The prototype had an aspect ratio of 6.0 and “very reduced” line consumption, explained Pierre-Yves. “The glider used a couple of four-cell-bridges to reduce line consumption.” However, these were “not perfect” and meant, “the overall curve of the leading edge was not as nice as expected.”

The profile was Pierre-Yve’s first sharknose design. “I based it on the profile of my latest EN-B design with the maximum thickness a bit further back.” In flight, he concluded, “The glider was nice to fly but it was missing aggression. Although brake pressure and turning was nice, thermalling could be better with more ‘bite’.”

After six months of flight tests, and reasonably happy, it was time for the second prototype.

Proto 2

Prototype 2 was born in May 2015. “It was based on the first proto,” said Pierre-Yves. “Planform, line distribution, internal structure were all very similar. The profile was updated to be more aggressive, with a more rounded front curve to help in the turn.”

The team increased the aspect ratio to 6.14 to get more performance, and also added mini-ribs to the trailing edge. However, the glider was still using heavier material than they planned for the finished wing. “Heavier cloth is much cheaper,” Pierre-Yves explained, “so we usually make the early protos from this, as going lighter usually only improves the wing.”

However, proto two proved to be a dead end. In the air at Gourdon it was immediately obvious that this was a different beast altogether to proto one. It was much more aggressive in pitch and I needed to constantly keep on top of it.

In the strengthening wind with choppy thermals the wing wanted to surge quite strongly. It had a nice turn but was far too much work. Definitely not suited to the mid-C market. On landing JC exclaimed, “Now you’ve done the hardest part!” Clearly, this proto hadn’t worked out.

Pierre-Yves agreed. “It’s a very demanding glider with a lot of pitch.” It was, he had concluded at the time, “time to think again”.

Proto 3

The third prototype, made in October 2015, was again based on the first proto but with a bit less aspect ratio at 6.05. This time they also went for lighter cloth as they hoped it would improve the handling.

Pierre-Yves’s production notes from the time reveal his thoughts: “It works good. Quite nice to fly.” The team then spent, “a few months” trimming it then gave it to other pilots for feedback.

At the time Supair were also working on the Leaf and were running late, so the EN C project was then put to the side for a few months.

“Early 2016 we met to discuss it again,” said Pierre-Yves. “We knew it was nice, but we believed we could do better. We decided to work on a completely new wing to see if we could get that something better. If we couldn’t, then we would finish proto three and then go for certification.”

Flying it at Gourdon I felt much more comfortable flying this wing than proto two. Gone, for the most part, was the aggressive pitching, although occasionally it felt like it wanted to jump forward.

With the wind getting up we called it a day.

Proto 4

The next day we were back on launch. Time for the next proto. Proto four was delivered in June 2016, and had a much-increased aspect ratio of 6.35. “There was a new profile, new planform, new line distribution, new front curve… lots of new things!” said Pierre-Yves.

“As soon as we started flying it last summer we decided this was much better than the previous path, super good, so we decided to concentrate on it,” he said.

In the air it felt remarkably well finished. Handling-wise it was far more like the original proto, but with a little more drive into the thermals.

It benefited from being more than 500g lighter, something that always makes handling that bit sweeter, and it also still maintained the secure feel of a mid-C, despite the aspect ratio rising to 6.35.

Performance is difficult enough to assess on a good day, let alone when you are flying on a windy stable day, but the climb rate seemed good, especially as I was flying right at the top of the weight range.

With this prototype performing so well, said Pierre-Yves, they knew they would only need “a few more updates” and they would have a wing that “100% matched our expectations”.

Proto 5

The final prototype, aspect ratio 6.35, arrived in October 2016. “The glider was what we wanted,” said Pierre-Yves. “Fast, climbing very good and easy to use for the category.”

There then followed the lengthy and involved process of trimming to get it ready for certification, before being put through load and EN tests. After that, “the Taska S was ready for production”. A few months later, the three other sizes were ready as well.

The production model

A few days after the prototype testing days in Gourdon a Taska arrived in my size – M. The final wing is a semi-light construction and makes use of lighter materials to keep the overall weight down; the M weighs 4.5kg. This is despite the fact the wing has 67 cells, and therefore uses more material than a glider with fewer cells. The lightweight materials have the added benefit of a compact packing size.

There are only four available sizes, although there is a good amount of overlap in the weight ranges between them. The total weight range only goes from 65kg to 120kg all-up though, so it is a little restricted for smaller or heavier pilots.

Bells and whistles

Comparing the prototypes with the finished production model turned out to be a good exercise for more than just comparing performance and handling. It also revealed the design details and finishing touches of the final product – everything that we all expect to see on a modern wing.

The sail has an obvious sharknose and 3D shaping at the front, with reasonably long reinforcement rods to help the shaping. On the trailing edge are Supair’s smart mini-ribs that avoid any external seams – a good thing if you often use rocky take-offs.

The line set is unsheathed, and the only colour-coding is a small amount of sheathing near the maillons. The lines themselves are grey and can be a little clingy when bunched up, but nothing too annoying. Only the centre lines have D-attachments, which gives the wing a clean look.

The racy-looking risers are well finished off and have widened clip-in points to stop them moving about in the karabiners. Colour-coding makes then easy to handle.

The brakes run through ceramic rings so there’s no risk of squeaky pulleys. The pulleys on the speed system are Harken and good quality. There are plastic balls on the C risers for rear-riser control: I prefer these to big handles as they are easy to use but there is less to get caught. When pulled down they also pull on the Bs so there is less deformation of the profile to keep glider performance.

Everything is finished off to a high standard.

Real-world performance

“Despite its 6.35 aspect ratio” is a phrase I found myself using when describing the wing to fellow pilots. It starts on launch where the behaviour is much nicer than you might expect from a long thin wing. The wing rises easily with light pressure on the As and then requires little control once overhead.

The only caveat is the short brake travel makes it easy to pull the wing down, so heavy-handed pilots need to bear this in mind. It does help when trying to kill the wing in windy conditions.

In the air the Taska feels remarkably cohesive – “despite its 6.35 aspect ratio”. The feel of the wing is very reassuring, with none of the flexing and bending you can get as aspect ratio rises.

Landing after battling hard-edged, stable conditions other pilots said the wing looked very planted and stable in the air, echoing the feeling that I had hanging below it. I found the workload in line with wings at the lower to middle of the C class. There was little pitching and rolling and what there was, was easy to control with the efficient brakes.

Entering thermals I didn’t find any tendency for the wing to pitch back or forward, it smoothly moved into the core with very little fuss. Once in, the brakes are direct and effective, allowing you to carve into a turn easily. Adding a little weightshift allows a good turn rate without slowing the wing. This gives it quite a playful feel.

Climb-rate on the Taska seems very good and I was happily keeping up with known performers in the EN-C class as well as higher level wings. And all this on a wing that feels remarkably easy to fly, more akin to the MacPara Elan than a Cure or Trango.

On glide the Taska feels very stable, with a nicely solid leading edge even at full speed. Bar pressure is moderate, making it easy to use often. I found myself making most transitions on at least first step.

Rear-riser control using the balls is effective and doesn’t seem to affect performance. Having heard that some people now use rear-riser control in thermals I gave it a try. It was easy enough to get the wing turning and to feel in control, although it would take me a while to adjust to the feel of flying this way.

At full acceleration I measured a true airspeed of 48km/h with trim being 38km/h – a healthy increase and fully usable. The glider seems particularly effcient at half-bar, and has a good feel of being powered up and more solid.

In conclusion

Supair can be rightly proud of their first sports class wing that combines great performance with good usability. Understanding the two-year development process has given me a real insight into the glider, and a greater appreciation of all the wings we fly and review.

Supair have ended up with a glider that looks good and feels good too. That secure feel and reasonable workload puts it firmly in the middle of the C class rather than being a D squeezed into the C.

The glider enters that C class in a busy year. The long-awaited Delta 3 is finally here, as is the latest incarnation of the well respected Sigma series. Czech favourites MacPara have the Elan 2 and Gradient have the Aspen 6. They are all hitting the market at about the same time. The Taska, I think, can justifiably stand tall in that busy market and is worth looking at if you are searching for a wing in this class.

****

The Prototype Process, with Supair designer Pierre-Yves Alloix

How many hours are typically flown on a prototype wing?

There is no hard and fast rule. On a final prototype we can spend 100 hours just to make sure it is exactly what we and the market expects. On the first prototype, well I once got rid of a glider after one flight because I knew it would be a waste of time to continue.

What actually happens when you get a new prototype?

We go straight to take-off – my philosophy is if the glider can stay over your head when you inflate it, then it means it can fly! During the first flight we try to adjust the trimming to get it flying at the speed we want, and we also take care of the wingtips’ sensitivity to collapse. Once the glider is flying at good speed, we focus on the turn behaviour: brake pressure, brake travel, turn initiation on roll or yaw axes.

What about the feeling?

We spend a lot of time on the general feeling of the wing. This can be a very long step as we might change the lines every day – we cut and sew them in our office. We try different front curves, different brake deflections, different line-set lengths. The aim is always to design and trim a glider that is pleasant to fly. Performance is just a bonus.

And when you think it’s ready, what then?

We send the wing to team pilots for approval. Most of the time those pilots are the target pilot for the model. We usually make a lot of ‘handmade’ changes, including trimming for certification, so I do a last ‘clean proto’ for certification, which includes all those handmade changes.

And finally?

When the glider is OK for certification we do a final check of the flight behaviour with the team – because it can happen that when we trim the glider in preparation for certification we change the flying behaviour. If all the lights are then all green, we go to certification and then start working on other sizes.

****

Manufacturer’s Specification

What Supair say: “More flight hours, more kilometres, more fun… the Taska offers a combination of in-flight comfort and performance on a par with the best”

Use: Cross-country adventures

Pilot level: Cross-country pilots

Sizes: XS, S, M, L

Flat area (m2): 22.5, 24.3, 25.6, 27.5

Recommended take-off weight (kg): 65-85, 75-95, 85-105, 100-120

Glider weight (kg): 4.0, 4.2, 4.5, 4.8

Cells: 67

Flat aspect ratio: 6.35

Certification: EN/LTF C

supair.com

Reviewed by Marcus King

To stay up to date and read our reviews first, subscribe to Cross Country